What is Murano Glass?

Murano Glass is glass that is produced in Murano, an island very close to Venice. It is deemed to be the most prestigious glass in the world and is one of the most renowned types of crafts worldwide.

How come it is known worldwide?

Because Murano production isn’t just stunning, it has also been produced by expert Venetian glass masters for over a thousand years!

Why is Murano glass called like that?

In the beginning, glass factories were mainly on the island of Venice. However, after one too many fires caused by glass factories in Venice, the local government prohibit the use of ovens for industrial production in the city of Venice.

Since then, glass factories were moved to the island of Murano.

But not all of them:

A part of the Murano glass production did remain and still exists, in Venice.

In fact, some artisans create small Murano glass crafts through the torching technique, which doesn’t require an oven. Therefore, those glass artisans could continue working in Venice.

Pronunciation tip: Murano Glass is pronounced “Moorano Glass”, not Morano Glass

Are you looking to buy authentic Murano Glass Art from trusted sources?

Contact us through our form

Looking for something in particular? Use our quick navigation:

The accidental discovery of glass

An ancient legend says that glass was created by chance on in Syria, where Phoenician merchants used saltpeter blocks to make a campfire on sandy riverbanks. The mix of these elements and the heat of the fire produced a new surprising material: glass!

Starting from 1000 B.C.E, glass spread throughout the Balkans and southern Europe. By the IV Century B.C.E., glass was known everywhere in the Mediterranean.

However, it was the Romans who first focused on glass production and who made its use widespread.

The invention of blown glass

Artisans invented glass-blowing in the I Century B.C.E in Palestine. This new technique brought new possibilities and greater flexibility for making glass objects.

For centuries, people associated glass-blowing to Murano glass. However, it is thought that Murano glassmakers initially inspired themselves to ancient crafts produced in Syria, Palestine, Greece, and especially Rome.

Want more tips, tools and stories from Venice, Italy?

We're on a mission to make it easy and fun to discover and support the authentic Venice. Try our email and see for yourself!

The History of Murano Glass

As mentioned above, it is thought that the first Venetian glassmakers copied elegant glassworks produced in the Middle East. Moreover, it is likely that Venetians even imported raw materials directly from that area.

However, by the XIV Century Venice was the leader in the art of glass making. This was due mainly to two reasons. One the one side, to its twelve glass factories producing everyday objects. On the other side, to the decline of the Islamic production to which Venice itself contributed.

In the XV Century, however, one thing in particular lead to the definitive success of the Venetian glass production: the invention of clear glass by Angelo Barovier. For the first time, glass was transparent and pure like rock crystal!

The success was immediate, and transparent glass works decorated with fusible enamels became a must for rich families, doges, and even the Pope.

Constant innovation is in the DNA of Murano Glass

However, the success of Murano Glass didn’t come just from the brilliant intuition of one man in the XV Century. In fact, the XVI Century saw the birth of several new techniques such as the “ghiacciato”, or iced glass, and the “filigrana”, or filigree, which is still very popular today.

It was during this time that the shift from artisanal to artistic production took place, delivering new shapes, colors and combinations highlighting the glass masters’ skills.

The first Murano Glass crisis

In the seventeenth Century, Murano glass artisans invented the “avventurina”, an extremely complicated process for creating a shiny and rock-hard vitreous paste. However, this century also saw an emigration of glassmakers from Murano to other parts of Europe.

This migration came as a result of financial difficulties that struck the Serenissima after two crisis. Firstly, a devastating plague in 1630 which decimated the population in Venice. Secondly, the birth of Bohemian glass which made competition harder than ever.

Murano glass saved through industrial espionage

Over the decades, the ever-increasing appreciation for Bohemian glass in Europe put the Murano glass industry on its knees. However, in the mid of the XVIII Century, Giuseppe Briati got hold of the secrets of the Bohemian production.

Briati adapted this new knowledge to the Murano artisans’ fantasy and expertise, helping the Murano glass industry to survive the crisis.

Briati’s greatest merit, however, is the invention of the famous glass chandeliers with multiple crystal arms, decorated with festoons, leaves and multicolored flowers, which boosted once more Murano’s popularity.

Apart from chandeliers, the demand grew also for engraved and decorated Murano mirrors, whose complex procedure was known since the XVI century.

Murano Glass after the fall of the Venetian Republic:

After the fall of the Serenissima in 1797, the Venetian guilds of arts and trades were abolished by Napoleon in 1806 and from 1815, when Austria took over, Bohemian products flooded the markets.

Many Murano glass masters emigrated, and countless secrets and techniques were lost. Apart from a constant beads production, the depression forced many glass furnaces to close: in 1820 only 16 furnaces were left and only 5 of those produced blown glass.

The rebirth of Murano Glass:

Here, particularly skilled and proud glass masters reacted to the crisis with innovation and revival of ancient techniques: researches on chalcedony and murrine, and the rediscovery of filigree and aventurine, sparked the rebirth that took place in the second half of the XIX century.

In the 1860s, Toso and Salviati furnaces produced ever more complex works testifying their incredible skills, producing crafts of unrivaled beauty and complexity.

These pieces got displayed and admired in exhibitions worldwide, making Murano once again the center of artistic glass production.

The XX Century: a new glorious era for Murano Glass

In the 1900s, furnaces began doing occasional works together with artists and designers, but in 1921 Venini decided to create the role of “artistic director”: the union between art, design and the Murano masters’ skills produced a great variety of forms of expression and styles.

Since then, artists such as Guido Cadorin, Alfredo Barbini, Umberto Bellotto, Carlo Scarpa and many others, began working on glass production with growing frequency. The works resulting from this union won prizes and awards at the Biennale and many international exhibitions.

After WWII, both the newly invented “submerged” glass technique (the overlapping of multiple layers of transparent glass) and the traditional blown glass technique worked using the “mano volante” (freehand), delivered once more pieces of outstanding quality and beauty.

Murano Glass today

The last big revolution took place in the 80s, when Murano glass masters, on one hand, felt the need to make their own creations rather than just producing the ideas of others, and on the other hand artists decided to learn themselves the art of glass making and glass blowing or to work in close contact with the masters to have a tight control over the making of their ideas and concepts.

Today, most of the Murano Glass production is imagined, designed, crafted, and priced for the luxury market. In fact, marvelous Murano glass crafts are often used to decorate 5-stars hotel and mansions around the world.

There are, of course, also smaller and more affordable authentic Murano glass creations. Such crafts include bracelets, earrings, necklaces, and glasses.

Ever wondered how Murano glass is made? Here’s a complete answer.

Already since childhood, everyone knows how glass looks like and its physical characteristics… but how is it made?

Because of the enormous role the famous glass produced on the island of Murano has played and still plays in the history and the wealth of Venice, we decided to collect here some information regarding this ancient art.

New techniques have been invented and others have been improved over many centuries, but the basics of Murano glass production are still those of over 600 years ago.

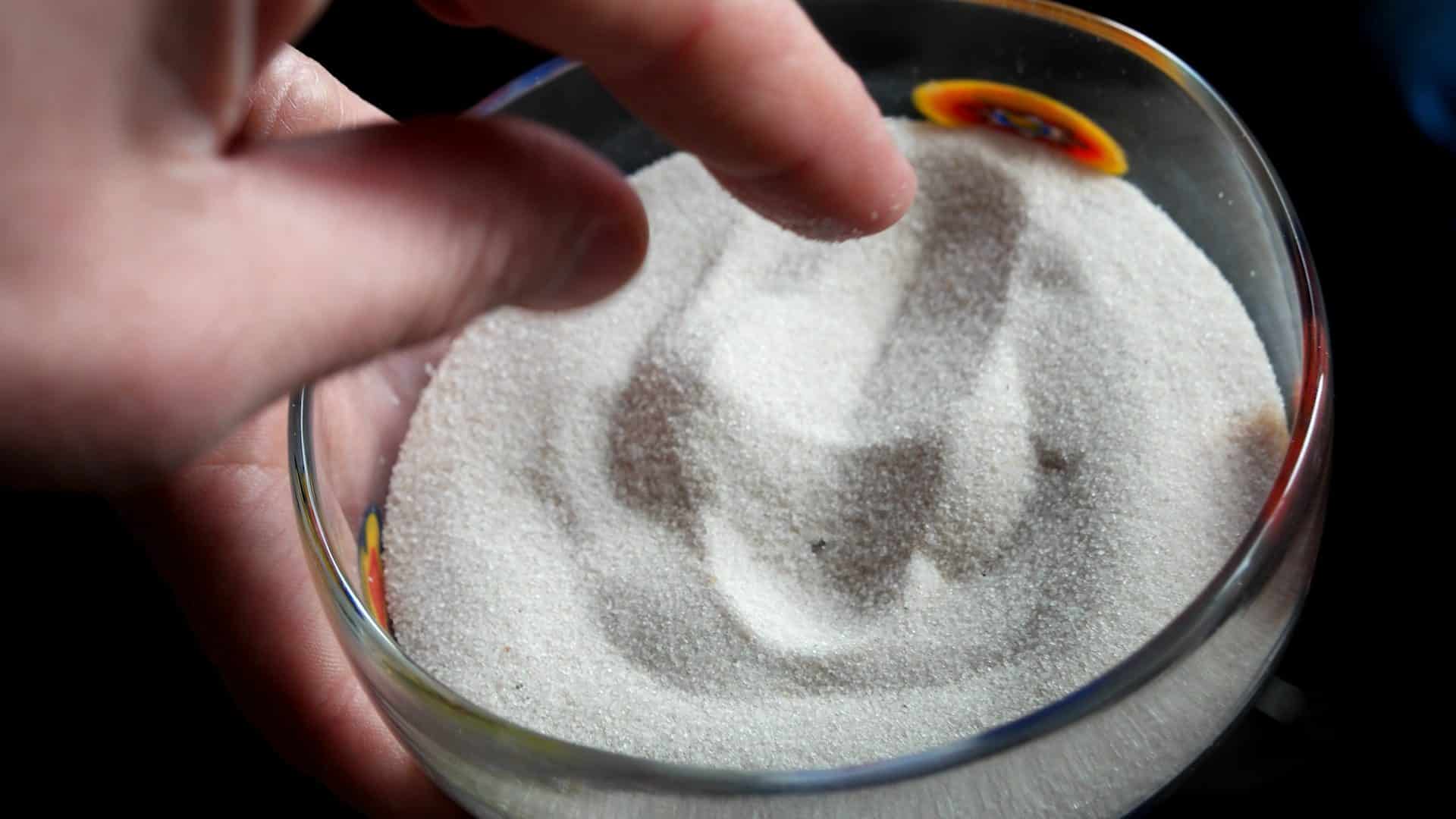

Raw Material

- Sand: silica 70%

- Soda: sodium carbonate

- Chile saltpeter: sodium nitrate

Check the following link if you are passioned about chemistry and want to know more about how chemicals are used for making glass

Fusion Process

The raw materials are mixed together in the heat-resistant crucible and then fused in a kiln that can reach up to 1.400°C.

The Murano glass in its basic composition is colorless. The colors are obtained by adding small amounts of minerals, oxides, and chemical derivatives to the base composition of the glass powder.

The Kiln

The kilns, “fornaci”, used nowadays on Murano have a large crucible of maximum capacity between 20-25 quintals. There are also kilns made up of a number of smaller crucibles (with capacity varying from 10kg to 2 quintals), the smaller crucibles being used for colored and opalescent glass.

Modern-day kilns on Murano are equipped with heat retainers and with equipment that makes it possible to control temperature and the rate of fuel combustion.

Murano Glass Operational Temperatures

Raw materials used for creating Murano glass are fused in a kiln at a temperature of 1400°C.

When the elements are fused together, the temperature of the viscous paste is lowered from 1400°C to 1100°C.

At this point, the paste is removed from the oven as it is “solid” enough to be shaped by the glass artisan.

When the artisan is done with his creation, he lets the glass set at a temperature of 500-600°C. The glass must be cooled slowly.

In fact, since glass is a poor conductor of heat, the inner and outer surfaces tend to cool at different rates. If the process happens too quickly, tensions within the glass can lead it to crack. Even some time after it has cooled completely.

This slow cooling process takes place in what are known as “annealing ovens”, where the temperature is slowly decreased.

Materials used to tune the proprieties of Murano Glass

There are some raw materials, called flux or melting agents, which soften at lower temperatures.

Sodium oxide, for example, slows down the solidification process. Therefore, it is often used in Murano for doing freehand glasswork or “a mano volante”. This way, in fact, the glassmaker has more time to shape the material.

Other raw materials often added to glass mixtures are sodium, nitrate, and arsenic. Sodium, for example, is used to make the glass surface opaque. Nitrate and arsenic, on the other hand, help to eliminate bubbles within the glass.

Other substances are added to glass mixtures to either color or opacify the final product.

How are complex Murano Glass pieces made?

To create complex Murano glass Pieces, the Master sets up and coordinates his team. The team, or “piazza”, consists of 2 or 3 people which help him in making of the piece.

The “serventino” handles the blowpipe. To do so, he takes molten glass from the kiln and rolls it against an iron plate, or “bronzin”.

The “servente” blows in the pipe creating a balloon, or “colletto”. He then rolls it again against the iron plate, to ensure symmetry. At this point, artistic work must immediately begin.

The Master quickly works with his tools on the viscous Murano glass mass whose temperature is rapidly dropping.

The Master must work very quickly for two reasons. Firstly, because if the temperature drops below 500°C, the glass becomes totally rigid and fragile. Secondly, because a sudden decrease of the temperature creates tensions in the glass and lead it to eventually break.

During the process, the Master often interrupts his work to let his team heat up the glass again. The temperature must increase but not too much, else the piece would lose its shape.

The heated piece is then handed back to the master who continues modeling it. If more material is required for the work, further glass is heated and added.

When the piece is done, it is put in a kiln (“muffola”) at a lower temperature than the main oven. The temperature is then slowly lowered (“tempera”) until it reaches the room temperature.

Famous Murano Glass Techniques

Murano’s glass history boasts a very long list of techniques. These techniques have been passed on and improved over centuries of work constant innovation.

Murano glass techniques can be divided into two main categories. There are so-called primary processes and secondary processes.

Primary processes are those that change the initial mix of elements before the melting process in the oven.

Secondary processes are those used to modify the final result. These include torching and fusing when the craft is still hot. Carving or sculpting when the piece is cold, or “a freddo”.

- Avventurina (colored glass with iridescent particles

- Beadwork

- Enameled glass

- Engravings

- Mirrors

- Murrina & Millefiori (sliced rods of colored glass fused together)

- Vetro Pezzato (multiple colored glass melt together, giving a patchwork look)

- Gold and silver leaf works

Murano Glass Main Techniques and Processes:

Acidato

The name Acidato refers to the use of fluohydric. The acid is used to etch the glass and create an effect is similar to sandblasting, but thinner and finer.

Avventurina

Avventurina is a translucent glass of yellow-brown color, in which copper microcrystals are dispersed causing a golden reflection.

To prepare it, a basic mixture for transparent colorless glass is melted with the addition of cuprous, iron and lead oxides.

To obtain the best result, the avventurina must cool very slowly. One way to obtain this is by switching off the oven and let it cool off over several days.

After the oven reaches room temperature, the crucible is smashed and the “avventurina” is found under a layer of colored glass.

The avventurina was highly popular in Murano in the mid-nineteenth century and it was often used for crafting Murano glass pieces for royal families in Europe

Alessandrite

Alessandrite involves the use of Neodymium oxide put into molten glass.

This addition causes the color of the glass to change with different lighting conditions. For example, artificial light produces warm tones, while fluorescent light gives blue tones. On the other hand, natural light causes the glass to show lavender colors.

Cristallo di Murano

Cristallo di Murano or “vetro bianco” (white glass), refers to a transparent and colorless Murano glass.

This glass, invented by Angelo Barovier in the XV Century, is produced by adding sodium calcium to the basic mix.

Another transparent glass is the famous Bohemian crystal. Unlike Bohemian crystal, however, Cristallo di Murano is excellent for freehand crafting and blowing.

Doublè

Doublè is a technique which includes a golden or silver decoration inside a glass work.

The first step is to engrave a decoration on a transparent glass with the use of a wheel. Then, the decoration is golded or silvered. Finally, a layer of transparent glass is put on top of the decoration.

At this point, the composition is put into an oven, where the parts join each other.

Francesco Andolfato invented this technique in the ’60s, to display yet protect decorations.

Filigrana

The “filigrana” (“filigree”) is a technique used since the XVI century which requires three main steps.

Firstly, a series of colorless glass rods with a colored inner core are arranged next to each other on a metal plate. This composition is then heated in an oven.

Secondly, a cylindrical mass of incandescent glass is rolled over the hot rods, for them to adhere to it.

At this point, the piece is worked on and finished as desired.

Fenicio

Fenicio is a kind of decoration which involves the use of white “lattimo” glass.

A layer of lattimo glass is put around the object and then engraved in a wavy pattern. The pattern is obtained by passing a metal comb, called “maneretta”, over the surface.

This technique owes its name to the fact that it was used by ancient Egyptians and Phoenicians to decorate perfume bottles and cruets.

Foglia d'Oro

“Foglia d’oro”, or golden leaf, is used to include a thin 24 karats gold leaf inside of the glass.

Murano glass artisans start by melting a small quantity of glass. Then, the glass is blown and shaped in the form of a cylinder. The artisan then rolls the hot glass over a gold leaf laying on a plate. After that, more glass is applied to envelop the leaf.

At this point, the master starts working on this mass, causing the thin gold leaf to break and to produce a series of golden straws.

Foglia d'Argento

Foglia d’argento, or silver leaf, is the same technique as the foglia d’oro.

In this case, however, the artisan makes use of a silver leaf instead of a gold leaf.

Fumato

Fumato is a technique used to give the impression of having smoke trapped inside of the glass.

To do so, a mass of glass containing small coloured particles is covered by a bigger and transparent layer of colorless glass.

To create the inner part of the piece, the artisan grooves the surface of the glass and exposes it to the smoke of a wooden oven. This causes particles of unburned carbon and ashes to adhere to it.

At this point, the master covers the piece with a layer of molten transparent glass.

Ghiacciato

Ghiacciato is a technique which gives the surface of the glass a kind of “craquelure”.

The effect is obtained by immersing the still hot piece for a few seconds in cold water and putting it back in the furnace. This process can be repeated several times in order to gain a stronger effect.

This procedure created a contraction of the volume in a thin outer layer, while the core remains hot, causing multiple small superficial cracks. Reheating the piece eliminates residual tensions, preventing the cracks to extend any further.

In the 20th Century, this technique was very appreciated for the making of bracket lamps, for the special way they would diffuse the light.

Lattimo

Microcrystals of calcium and sodium fluorides in the glass reflect light, determining both opacity and white “milky-like” coloring.

In order to obtain this effect, fluorine compounds, such as cryolite or fluorine spar, are added to the glass mixture.

Introduced in the XVI century for items decorated with multicolored enamels, the Lattimo was later used as a complement to other processes.

Mirrors

At the end of the XII century, Venice and Nuernberg became popular for their innovative mirrors’ production, consisting of a layer of transparent glass covered on one side with a thin layer of silver or aluminum.

Nowadays, modern mirrors are produced by spraying, under vacuum, the surface of the glass with a thin layer of silver or aluminum and then fixing it via electrolysis.

Murrina

A bundle of multicolored glass rods is arranged so that its cross-section displays a certain design.

This composition is then heated to its melting point and pulled until the desired diameter. After cooling, the rod is cut into disks of variable thickness, ranging from a few millimeters to a couple of centimeters.

These disks can be used in two main ways. One possibility is to set up some murrine on a metal plate, heat them up to their melting point in the kiln and then roll a cylindrical mass of incandescent glass over them, in order for the murrine to adhere to it.

Another possibility, largely used for the executions of dishes and bowls, consists in arranging the murrine inside a mold, filling the empty spaces with the glass mixture, and then heating it up to form a single object.

After the cooling process, the item is finished off with the use of a grinding wheel.

Millefiori

Millefiori or “a thousand flowers”, is a particular kind of “murrina”, in which the cross-section of the rods used for the initial bundle is made of concentric layers of different colored glass with a star-shaped core.

The use of the “millefiori murrina” is the same as the use of the “murrina”.

Mulatura

Molatura is a process for cold-processing glass surfaces, obtaining desired decorations.

There are two main methods: one uses silicon-carbon tips, has short operating times, but gives rougher results; the other, with the use of copper tips dipped in grinding powder, has longer operation times but gives more accurate and elegant results.

Due to its composition, however, Murano glass does not perform greatly with such techniques.

Opalino

Opalino, is a slightly different version of “Lattimo”, and it creates an effect similar to an opal, an iridescent white-blue stone.

Rugiada

This technique, invented by Ercole Barovier in 1940, consists of applying colorless glass on the surface of an object during its production.

When the object is then reheated, the particles are partially melted and adhere perfectly.

Due to the pleasant light diffraction effects, this technique is appreciated for bracket lamps.

Smalti

Enamels are applied on the item while cold, and once the decoration is finished, the item is placed in a small “muffola” at 550-600°C where the enamel will fuse without deforming the item.

Enamels must fuse at a temperature lower than that of the glass, their colors should not fade at high temperatures, and they should have a coefficient of expansion as close as possible to that of the glass of the item, to prevent breakages during the cooling stage.

Soffiato

The technique of the glass blowing dates back to the I century B.C.E. The mix of glass is put in the furnace until it melts.

The blowpipe tip is heated up and is used for taking the molten glass and rolling it on a flat sheet of steel called “bronzin” (marver): this forms a cool skin on the exterior of the molten glass blob and shapes it.

The Master then blows air into the pipe, creating a bubble, and if needed more glass can be cast over it to create a larger piece.

Once the final size has been reached, the bottom is finalized and the blowpipe is removed from the top to provide an opening or to finalize the piece.

Sommerso

In the “sommerso” or submerged, a layer of colored glass enclosing air bubbles and gold leaves is coated with a colorless transparent layer of a few centimeters.

Sabbiatura

Using an air compressor, sand or alumina powder is sprayed on the glass item, causing micro fractures that make it opaque.

The effect which can be controlled by changing the intensity of the air and the size of the particles, has the advantage, unlike the “etching” technique, of not making use of toxic components.

Vetrofusione

Glass fusing is a technique used to join glass pieces together by partly melting them: two or more pieces of glass are laid on top of each other or overlapped and are warmed until a temperature of 750-850°C, at which point the glass will fuse onto each other.

Glasses with different coefficients of expansion cannot be fused together, for upon cooling the piece would crack.

Shopping for Murano Glass Art and Jewellery, the frequently asked questions

There are a few common questions that always come up when visitors desire to shop for authentic Murano Glass crafts. You can find our answers below, along with some tips and considerations.

What kind of objects are made in Murano Glass?

There are two main types of objects made in Murano Glass: beads used to make beautiful jewels and art pieces ranging from sculptures to vases, glasses, and chandeliers.

How much does Murano Glass cost?

Murano Glass can cost from 30 euros for the most simple jewelry, to a few thousand euros for a Murano Glass vase, to dozens of thousand euros for big Murano Glass chandeliers, for example.

How much does Murano Glass Jewellery cost?

Earrings, bracelets and simple necklaces in authentic Murano Glass can be found for anywhere from 30 euros to under 100 euros. The more beads the more expensive a Murano Glass jewel is. Rich necklaces usually cost up to a few hundred euros.

The prices vary with the number of beads and their rarity. Beads which require more work or are no longer in production such as antique beads, tend to cost more than most common ones and so do the jewels created with them.

How much does Murano Glass Art cost?

Murano Glass Factories produce entirely hand made art pieces such as chandeliers, sculptures, and vases which are pure art and request long hours of expert work. Prices are the ones you would expert for art and one who wants to buy Murano Glass Art should be ready to spend anywhere from a few thousand euros.

The prices for Murano glass art vary according to several factors:

- The techniques used to execute the piece. The more complex, the more work required, the more expensive the piece.

- The brand you are buying—especially Barovier & Toso, Moretti, Pauly, Seguso, and Venini—command higher prices than others because of the quality of their work and the long tradition behind their names.

- The fact that the piece is designed or signed by a big-name designer as recently well-known fashion designers have designed pieces for some of the top glass producers. These signed pieces limited editions come at a premium.

- The history of the piece is another factor determining the value of it. Documented antique in good condition, can be sold for six figures at auction, for example.

Where should I buy Murano Glass?

Because of the sea of fake Murano Glass, we recommend you to buy jewels or artwork only at trusted vendors.

You should buy Murano Glass jewelry directly at local artisans’ boutiques and workshops.

There are plenty of shops selling overseas mass produced products pretending to be “made in Italy” or in Murano Glass.

To be sure not to spend your money in the wrong place and to get the real thing while supporting local businesses, both look for the handpicked and vetted shops on this list and for our logo on their door and windows.

If you buy a digital pass, called the Venezia Autentica Friends’ Pass, you will also unlock a 10% at all our partner local businesses while helping us to keep on supporting them, for free. Read more about the Friends Pass, here.

Where can you buy Murano Glass Art and furniture?

Chandeliers, glass, vases and all Murano Glass pieces should be bought only directly at the Glass Factories in Murano or from authentic galleries in Venice.

Unfortunately, many shops in Venice sell fake Murano Glass. Not all are the items sold not at all original handmade Murano Glass, but they are often quite ugly. They are nowhere close to the beauty and quality of the actual work of Murano Glass Masters.

If you want to purchase authentic Murano Glass art either in person or online, contact us at the form below.

Please be aware that prices are “high”, usually starting at a few thousand euros. Indeed, every Murano Glass chandelier, vase or sculpture is unique and made entirely by hand by highly trained & skilled Murano Glass Masters.

Are you looking to buy authentic Murano Glass art, vases, and chandeliers? Get in touch with us to make sure you spend your money in the right place! We can put you in contact in person or online with the best glass factories in Murano.

Please, be aware that prices for Murano Glass art, vases and chandeliers commonly start at 4-5.000 euro.

How can I be sure that a Murano Glass piece is authentic?

The only way to be sure to buy authentic Murano Glass is to buy from official and vetted boutiques, galleries or factories referred to you by a trusted expert source. In fact, vendors of ‘knock out’ do not hesitate to lie about the authenticity of their product or to produce fake certificates of authenticity.

A very easy way to make sure you’re buying authentic crafts and authentic Murano Glass is to check out the shops we recommend or, if you’re looking for bigger pieces, to contact us.

Murano Glass Experience

Murano Glass Shopping ExperienceLearning more about Murano Glass: Demonstrations, Workshops and Museum

Can I watch Glass Masters at work?

When visiting a glass factory to buy glass work, the first step will generally be to take you to a 10-30 minutes demonstration of the glass master’s work.

This is beautiful to see and helps you understand the work behind the pieces you will then see as you will usually be able to ask questions to an expert explaining what is happening in front of your eyes.

However, this is not meant to be a free demonstration for visitors who do not attempt to buy anything and is hardly worth the travel to Murano if what you want to see is the work of the artisan. Glass Art sellers are highly skilled and will immediately see through your ‘game’ and quickly usher you out of their factory or else take you on a long walk through the showrooms working hard to sell you something.

This behavior from the sellers is understandable as glass factories are expensive to run and, like anywhere else, rely on customers money to survive.

The best and most rewarding way to see the work of glass masters is either to pay a high fee for a private demonstration at a factory or discover the art of beadmaking instead to enjoy a fully personalized and immersive experience and give it a try yourself.

Can I learn to work Murano Glass myself?

Yes! As a visitor, you can be initiated to the art of Murano Glassmaking by using the torching technique to make Murano Glass Beads.

You can book a bead making experience with an expert artisan, here. If you are looking to learn enough to be autonomous and are in Venice long enough to dedicated numerous hours to your training, don’t hesitate to let us know. This is something we will happily help you with, too.

It is not possible to learn to work bigger pieces as it would be too difficult and dangerous for a beginner.

Do you recommend me another activity to learn more about Murano Glass?

If you are interested in the incredible history and beauty of Murano Glass, we strongly recommend you to visit the Murano Glass Museum

This museum collection showcases unique glass pieces going from as far back as to the 5th-century B.C.E, until the contemporary glass crafts. A must see!

You made it to the bottom of this long article, congratulations!

Since you’ve made it this far, we understand you’re very interested in knowing more about the authentic Venice. Therefore, we invite you to check out the resources below to find useful information for your next visit and discover how to make a positive impact on the local population:

I'm visiting Venice. Why should I follow your recommendations?

The way you visit Venice has an impact both on the quality of your experience and on Venice itself. Chilling, exploring, shopping, eating and drinking where the locals do, can make a huge impact both on the memories you bring home and on the local economy and community.

Home >> Venice and Venetians >> Venice Explained >> You’re Here

Facts, Curiosities, History of Venice, Italy

More about life in Venice, Italy